As a result of the extensive storm damage, one of the most comprehensive roofing investigations of a hurricane stricken area took place shortly after Hurricane Charley made landfall. RICOWI (Roofing Industry Committee On Weather Issues) volunteer investigators, including wind engineers, roofing material specialists, insurance analysts, structural engineers and roofing consultants trained on wind issues, were immediately dispatched to south Florida.

Although the RICOWI teams have been in place since 1996, there has not been a wind event that met the criteria of a windstorm until Hurricane Charley hit Florida in August. "The criteria clearly states that a storm must have sustained wind speeds of 95 miles per hour or greater when it makes landfall on the continental United States, and the storm must hit a populated area," states RICOWI chairman Joe Wilson. "After Hurricane Charley, seven teams were deployed and investigations on all types of roofing systems began. Members of the Federal Emergency Management Agency also assisted the teams."

A profile will be developed based on the data collected from RICOWI's investigation. The report will highlight a number of issues including the performance of various roofing systems in severe wind events. This will lead to overall improvements in roof system durability, the reduction of waste generation from re-roofing after extreme weather conditions and a reduction in insurance losses that have historically led to increased costs for homeowners. The report should be released during the first quarter of 2005.

Naturally, homeowners and contractors want to know how metal roofing held up in the extreme Florida weather conditions. Most metal roofing systems have a 120-mph wind rating and uplift resistance that is above new building code requirements. In other words, metal roofs are able to withstand wind gusts equal to an F2 tornado. Pete Croft, Metro Roofing, joined the RICOWI team for investigation. "It is apparent that homes constructed after Hurricane Andrew in 1992-in accordance to the upgraded building codes-were better able to withstand the extreme forces of Hurricane Charley. On the other hand, older homes that were built prior to Andrew did not hold up as well," says Croft.

Metal roofing is typically used in various climates, including those subject to extreme wind conditions. Metal roofing is unique because fastening patterns can be adjusted as required to meet different climate conditions. Metal materials have a very high strength-to-weight ratio that makes them ideal for harsh climates. Experience has shown that systems performed very well when they were well designed and when properly installed.

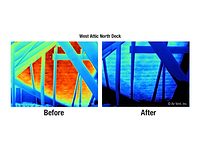

Many times, it is not the roof that fails during extreme weather, but the underlying structure, such as the roof deck itself. The entire building must be built to withstand the effects of wind. The key factor for roofs that survived the recent hurricanes seems to be the proper fastening of the roof covering.

A proper roof installation should not rely only on the exterior materials. Quality underlayments are essential to a roof's performance. Many metal roofing manufacturers strongly recommend using heavy felt or some of the newer synthetic materials. The actual metal roof should be adequately anchored in the event that the exterior materials become damaged. Current building codes typically address this issue and require a stricter fastening of the materials in hurricane-prone regions.

"Metal roofing materials interlock, forming a protective barrier that other roofing materials do not provide. This interlocking makes the roof stronger and more resistant to high winds," states Bill Hippard, president of the Metal Roofing Alliance. "I believe the RICOWI report will lead to even better quality, higher performing roofing systems."

The MRA has always supported quality products and continues to support initiatives that lead to improvements. For example, the recent launch of the Certification Program, an initiative by the Metal Construction Association, has helped the industry grow and prosper. This scientific testing program ensures contractors and homeowners that the painted surfaces of metal roofing products will stand up to the toughest standards. This initiative differentiates the levels of quality, creating a credible basis for product comparison and providing a means of verifying metal roofing performance.

In addition to using quality roofing products, installation is the key to a roof's longevity. "Contractors who join the MRA are sponsored and trained by MRA manufacturer members. The contractors listed on the MRA Web site are the most qualified contractors in the field," continued Hippard.

"From the very beginning, one of our key objectives has been to increase the number of metal roofing installers in the United States and Canada. Many roofers and contractors don't realize that the metal roofing industry has changed dramatically over the last several years. There are a number of new products on the market that are easier to install and the margins on metal roofing products are very attractive," explains Hippard.