At the corner of Woodward and Jefferson in downtown Detroit, the Coleman A. Young Municipal Center houses courtrooms, city offices and the mayor’s office. It’s also famous for the statue that abuts it-Marshall Fredericks’ bronze statue “the Spirit of Detroit”-or, as it’s also known, the Jolly Green Giant. Recently, at the same time the statue was being refurbished, a splash of green was added to the building’s rooftop in the form of a garden roof.

The story of how the green roof took root there illustrates the ingenuity of a contractor, manufacturers and city officials who found a way to include a garden roof without incurring additional costs or additional weight.

When it came time to restore the roof at the Coleman A. Young Municipal Center, the crumbling pavers were replaced with a modular garden roof system from ELT Easy Green.

Daniels’ company had been servicing the roof and restoring and replacing the flashings on a service contract, so he was familiar with the building. He had a hunch that the roof could be restored for far less than the cost of a roof replacement.

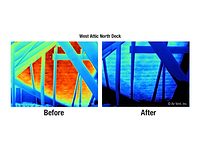

“As we removed the pavers and got down to the membrane, we found it was in excellent condition,” said Daniels. “It had been protected from ultraviolet radiation by the pavers, and since the wall flashings had been well maintained, there were no problem areas at the perimeter.” After the membrane was power washed, no leaks were found, so Daniels recommended that the roof be restored. He put together a proposal to restore the membrane with Thermo Materials’ SEBS Reflective Liquid Roof coating, replace the insulation and covering, and re-use the existing pavers that were in good condition. As for the pavers that were crumbling, Daniels recommended that they be replaced with a section of rooftop garden made up of modules from ELT Easy Green.

Checking their handiwork after the completion of the project are (standing, from left) Domenic Morelli of Thermo Materials, David Morency of Bright Roofing and Restoration, David Billing of Tri-R Products, T.J. Daniels of Bright Roofing and Restoration, John Townsend of Bright Roofing and Restoration, (kneeling, from left) Jim Rizzo of Bright Green Technologies, and Lee Daniels of Bright Roofing and Restoration. (Photos by Chris King.)

The plan is to expand the green roof each year as the city’s budget allows by simply removing existing pavers as they fail and adding green roof modules. “It’s a win-win for the building,” Daniels said. “As the green area gets bigger, the urban heat island effect is minimized, and the bumblebees will come back. Plus, it turns into an item for the maintenance side of the ledger rather than a capital expense for the building.”

It took about an hour to install the ELT Easy Green modules. The plan is to expand the green roof area year by year as the city’s budget permits.

A Successful Project

After the pavers and insulation were removed and the existing membrane was power washed, it was coated with SEBS Reflective Liquid Roof from Thermo Materials. The seams were coated with three courses of SEBS and SB-075 polyester, then the entire field assembly was coated to increase the water-tight protection, extend the life of the EPDM, and qualify as an ENERGY STAR coating. Once the coating cured, the insulation board and protection pad were re-installed. The system was then covered with the remaining pavers and the ELT green roof surfacing.The crumbling pavers were ground up to dress up the edge of the garden roof area, eliminating the expense and labor of removing them. The 20,000-square-foot project took three days to complete, with the 500 square feet of green area serving as the final piece of the puzzle. “The ELT panels went down in about an hour,” said Daniels.

When the plants in the pre-grown modules were spread out, the seams between the panels weren’t even visible minutes after installation. “Instant gratification,” Daniels said. “It’s a sedum carpet.”

“The logistics of accessing the roof areas with our products is always a key problem,” said Daniels. However, his restoration plan solved access problems beautifully. Everything was easily taken up in the freight elevator and walked up the final flight of stairs to the roof. Here, the lightness of the ELT panels was a big help. “We put them in when they’re a little dry, then water them as they’re installed,” he said. “The panels are 1 meter square-about 39 inches by 39 inches-and each panel can weigh 120 pounds soaking wet, but they’re significantly lighter when dry.”

Since the insulation and pavers were re-used, very little material came back down the elevators. This was a plus, as Daniels soon found out that the mayor and judges made frequent use of the freight elevator to get around the building. However, there was no disruption of city business of courtroom activity as a result of the project. “We were very quiet,” said Daniels.

The roof of the center is visible from several high-rise buildings, including GM’s corporate headquarters in the Renaissance Center, visible in this photo behind Ivory Burks (left) and T.J. Daniels of Bright Roofing and Restoration.

A Resourceful Partnership

When asked why the ELT green roof system appealed to him, Daniels cited its versatility. “It can be lightweight or heavyweight, flat roof or steep slope, pre-grown or grown in place,” he said. “It works with new construction and retrofit applications. It can be used on all slopes from dead level all the way to vertical, and it can manage northern climates as well as southern climates.”Daniels and Jim Rizzo, co-founder of Bright Green Technologies, are hoping that green roofs and vertical living walls will flourish in Michigan and throughout the country.

“We were looking for a retrofit green system that was lightweight, and we found it in ELT Easy Green,” said Rizzo. “We think retrofit is the way to go-it’s the market with the most potential. With the green roof market, the issue is how do roofing contractors get their arms around green. The answer is lightweight retrofit systems with warranties from major manufacturers.”

“There’s a new mentality when it comes to green roofs,” said Daniels, who noted that he has received several calls from occupants of nearby buildings that look down on the Coleman A. Young Municipal Center. “The mindset has changed a little. It used to be building owners would say, ‘I have a roof leak; I need to call a roofer.’ When it comes to green, they say, ‘I want green; can I afford it?’ It’s a paradigm shift.”

For more information about ELT Easy Green, visit www.elteasygreen.com. For more information about Bright Green technoloigies, visit www.brightgreenroofs.com. For more information about Bright Roofing and Restoration, visit www.bright-roofing.com. For more information about Thermo Materials, visit www.thermomfg.com.