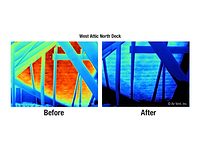

What's in the Attic?

Residential re-roofing contractors are by

definition working on a building that could have underlying problems, including

improper ventilation, undiagnosed roof leaks and mold.

Residential re-roofing contractors are by definition working on a building that could have underlying problems, including improper ventilation, undiagnosed roof leaks and mold. Roofing Contractor spoke with Steve Henderson, Vice President of DCI Products, a manufacturer of ventilation products for the roofing industry, and asked him some questions about proper attic ventilation.

Roofing Contractor: When the contractor does the inspection and proposal for a re-roofing job, what things should he be on the lookout for?

Steve Henderson: Proper attic ventilation is a key ingredient to a proper roof replacement - especially in the energy-efficient world we are living in. Proper underlayment is another key part of doing the job right. Wall flashing is an area that still needs some attention. If a contractor starts with a quality ice and water membrane at the eaves and finishes the course against a wall with ice and water membrane, he should have everything covered. SmartVent was designed to be an easily installed roof top intake vent for even the snowiest regions of the United States and Canada. Following the step-by-step instructions ensures that the roof will be adequately ventilated through all four seasons.

RC: Do you recommend an attic inspection as part of every job?

Henderson: Yes, because the attic affects the efficiency of the roof system and the warranty of the shingles. An inspection of the attic should be done at least during installation of the roof system. That should be a separate proposal for any inefficiencies that are found since it is not related to the actual shingle installation work. The homeowner may want to take that responsibility on his own, but whoever does the inspection, it must be done at the start of the work. Nonetheless, the contractor should always make the homeowner aware of the importance of a properly designed and functional attic space for operation of the accessory items to the roof system as well as the energy efficiency and warranty issues. The first step is a quick assessment of possible ventilation concerns such as gable vents with ridge vents, no soffit overhang, bathroom fans venting directly into the attic because no pipes are visible. Other items might not be easily accessible to quote an estimate such as moldy plywood, lack of adequate insulation, insulation blocking airflow, etc. These items should be discussed prior to the work being done. The pricing should be discussed in generalized form prior to the jobsite inspection. Going in with a fair price and performing professional services once on the job is an asset to a roofing company.

RC: What are some common conditions that can lead to mold growth in roof systems and attics?

Henderson: There are several common problems that can lead to mold growth, including:

Henderson: Generally the cold, snowy climates have the mold and winter ice leaks associated with condensation and ice dams. The southern, non-snowy regions are faced with high winds and severe heat. Ventilation is key in both cold climates and warm climates.

RC: If there is improper ventilation, how can this situation be remedied as part of the re-roofing project?

Henderson: Install intake ventilation such as the patented DCI SmartVent and a comparable ridge vent such as the DCI SmartRidge. An attic inspection as part of the project should be recommended, possibly at an added cost. This is where your professionalism kicks in and that is probably why they hired you, the contractor.

For more information, visit www.dciproducts.com.

Residential re-roofing contractors are by definition working on a building that could have underlying problems, including improper ventilation, undiagnosed roof leaks and mold. Roofing Contractor spoke with Steve Henderson, Vice President of DCI Products, a manufacturer of ventilation products for the roofing industry, and asked him some questions about proper attic ventilation.

Roofing Contractor: When the contractor does the inspection and proposal for a re-roofing job, what things should he be on the lookout for?

Steve Henderson: Proper attic ventilation is a key ingredient to a proper roof replacement - especially in the energy-efficient world we are living in. Proper underlayment is another key part of doing the job right. Wall flashing is an area that still needs some attention. If a contractor starts with a quality ice and water membrane at the eaves and finishes the course against a wall with ice and water membrane, he should have everything covered. SmartVent was designed to be an easily installed roof top intake vent for even the snowiest regions of the United States and Canada. Following the step-by-step instructions ensures that the roof will be adequately ventilated through all four seasons.

RC: Do you recommend an attic inspection as part of every job?

Henderson: Yes, because the attic affects the efficiency of the roof system and the warranty of the shingles. An inspection of the attic should be done at least during installation of the roof system. That should be a separate proposal for any inefficiencies that are found since it is not related to the actual shingle installation work. The homeowner may want to take that responsibility on his own, but whoever does the inspection, it must be done at the start of the work. Nonetheless, the contractor should always make the homeowner aware of the importance of a properly designed and functional attic space for operation of the accessory items to the roof system as well as the energy efficiency and warranty issues. The first step is a quick assessment of possible ventilation concerns such as gable vents with ridge vents, no soffit overhang, bathroom fans venting directly into the attic because no pipes are visible. Other items might not be easily accessible to quote an estimate such as moldy plywood, lack of adequate insulation, insulation blocking airflow, etc. These items should be discussed prior to the work being done. The pricing should be discussed in generalized form prior to the jobsite inspection. Going in with a fair price and performing professional services once on the job is an asset to a roofing company.

RC: What are some common conditions that can lead to mold growth in roof systems and attics?

Henderson: There are several common problems that can lead to mold growth, including:

- No ventilation at the eaves or at the ridge.

- Bathroom fans exhausting air into the attic.

- Leaks at penetrations and terminations.

- Insulation blocking airflow anywhere from soffit to ridge.

- Multiple exhaust vent devices will short circuit the passive flow.

- Installation mistakes caused by not following manufacturer’s directions.

- Structural wood beams blocking airflow somewhere between soffit and ridge.

- Improperly ventilated areas including valleys and the areas around skylights and chimneys.

Henderson: Generally the cold, snowy climates have the mold and winter ice leaks associated with condensation and ice dams. The southern, non-snowy regions are faced with high winds and severe heat. Ventilation is key in both cold climates and warm climates.

RC: If there is improper ventilation, how can this situation be remedied as part of the re-roofing project?

Henderson: Install intake ventilation such as the patented DCI SmartVent and a comparable ridge vent such as the DCI SmartRidge. An attic inspection as part of the project should be recommended, possibly at an added cost. This is where your professionalism kicks in and that is probably why they hired you, the contractor.

For more information, visit www.dciproducts.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!