Earlier this year, Air Vent wrapped up its 15th season presenting its educational Attic Ventilation: Ask the Expert™ seminars. Thanks to the generous participation of more than 27,000 attendees, the program has evolved into a collection of best practices and things to avoid in residential and light commercial attic ventilation. After more than 600 seminars across 44 states and Canada, here’s what we’ve learned about roofing contractors.

They Ask a Lot of Questions

Generally, roofers want to do the job right. And when they are unsure or want to confirm their game plan, they ask questions in an effort to better understand the relationship between attic airflow, roof geometry, climate conditions, vent design, etc. The seminar provides a forum to ask those questions in person. Many times fellow roofers (yes, the competition!) participate in the answer. Here are the five most frequently asked questions we continue to hear.

1. Is it possible to have too much attic ventilation? It’s possible to have too much exhaust ventilation, but you cannot have too much intake ventilation. If there is more intake ventilation than the attic’s square footage requires, it’s not problematic because any excess intake converts to “exhaust” on the leeward side of the house. However, the same is not true when it comes to exhaust. If there is more exhaust ventilation than the attic’s size requires — and that extra exhaust is not balanced with equal intake — it’s potentially problematic. An exhaust vent lacking intake can pull needed intake from itself (ridge vent) or from a nearby vent (from one wind turbine to another; from one roof louver to another).This can lead to inefficient airflow movement and weather infiltration.

2. Can multiple types of exhaust vents be used on the same roof? It’s not recommended. Air follows the path of least resistance. For optimum attic ventilation purposes, that path is supposed to be from low in the attic (intake vents) to the highest possible exit point on the roof (exhaust vents). If two different types of exhaust vents are combined (ridge vents, power fans, wind turbines, roof-top louvers and gable-mount louvers) the primary path of air becomes the distance between the two types of exhaust vents (for example, the distance between the gable louver and the ridge vent). That can short-circuit the attic ventilation system and lead to inefficient airflow and weather infiltration through one of the exhaust vents that have suddenly become an intake vent.

3. Is exhaust ventilation without intake better than zero ventilation? No. Both scenarios are potentially problematic. For the exhaust vent to work properly, it must have an equal amount (or more) of intake. That ensures efficient distribution of airflow inside the attic. Furthermore, without intake, an exhaust vent could ingest air/weather from itself or from a nearby exhaust vent (see Question 1). And if an exhaust vent is ingesting air, it could also ingest whatever the air is carrying at that moment (rain, snow, debris, etc.). On the other hand, an attic without ventilation faces potential troubles associated with heat and moisture buildup as well as ice dams in cold climates. Pick your poison.

4. What’s the best way to ventilate a roof with multiple ridge heights above a common attic? The basic rule for ridge heights states that all ridges can be vented whether they run parallel or at angles to each other. If, however, the ridges are more than 3 feet apart in height, only ventilate the higher one or separate the attics. As wind passes over an externally baffled ridge vent, it creates low static pressure, drawing air from the attic. The faster the wind moves over the baffle, the greater the pressure it creates. Typically, wind moves faster at higher elevations, therefore, the higher ridge will be exposed to high wind speeds. If the wind speed difference is adequate, the pressure at the higher ridge may be enough to pull air through the lower ridge vent. Thus, it’s best to separate the attics with plywood or poly sheeting to create two distinct attics. Once the attics are separated, ventilating all of the ridges is acceptable.

5. Can roof louvers be used low on the roof as intake vents? It’s not a good idea because roof louvers are designed to be exhaust vents, not intake. If a roof louver is bringing in air it could also be bringing in weather. Furthermore, roof louvers placed low on the roof will see an increased volume of watershed at an increased speed from higher points on the roof compared to their intended position a few feet from the roof peak. There are a variety of intake ventilation options available (rectangular undereaves, continuous soffit, vented drip edge, mini-louvers, and roof-top shingle-over edge-of-roof vents) without having to misuse roof louvers.

The Elite Separate Themselves From Everyone Else

By participating in educational seminars, roofing contractors demonstrate their commitment to quality work. However, listening to them explain how they estimate the job, present the plan to the homeowner and then do the actual work reveals additional strategies that help separate some roofers from others. Here are five “difference makers” that caught our attention.

1. Attic inspections get noticed. Conversations with roofing contractors who routinely inspect attics as part of the estimating process have convinced us of this: Generally, homeowners will reward thorough roofers with the project. When they are safe and practical, attic inspections can make a difference.

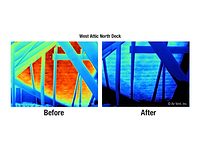

2. Photos are a powerful tool. Digital photography has simplified the process of obtaining and sharing photos. Roofers who provide homeowners with a compelling visual of what’s happening on their roof and inside their attic make it easier for them to understand the need for the work being recommended. Before-and-after photos from previous projects that had similar troubles can give the homeowner peace of mind.

3. Third-party documentation packs a punch. Roofers who face resistance from homeowners about the need for balanced attic ventilation point to third parties for support. These include Asphalt Roofing Manufacturers Association, The Engineered Wood Association, shingle warranties and building codes. By referencing the requirements and recommendations of third parties, roofers strengthen their position that they really do have the homeowner’s best interests in mind.

4. Using the manufacturer’s tools lands more jobs. Many of the resources and tools that Air Vent offers were suggested by roofing professionals. And those who use, for example, the customizable online calculator, the attic ventilation checklist and video clips demonstrating vent performance tell us they increasingly land the job compared to the other contractors.

5. There’s a time to walk away. As difficult as it is to walk away from potential business, roofers tell us they are ready and willing to do it if the homeowner presses them to do the job counter to what the roofer knows is best. And if the homeowner is unwilling to pay the roofer’s fair asking price for a balanced attic ventilation system because another bid is significantly lower, roofers tell us they walk away before compromising their pricing model and lowering their quality standards. Why? Because passing on a project that does not fit the roofer’s business is better than a callback.

Thankfully, roofing contractors are generous. We know this firsthand because they share tips from the field, job photographs, and mistakes to avoid that we in turn incorporate into our seminars. This invaluable information sharing is one of the main reasons our seminar remains popular with roofing professionals.

We will continue to offer the free Ask the Expert seminars, and we are active members in the Roof Assembly Ventilation Coalition, whose mission is to be the leading authority and technical resource on ventilated roof assembly design and performance.