Mule-Hide Products Co. Introduces Roof Drains for New Construction, Retrofit Applications

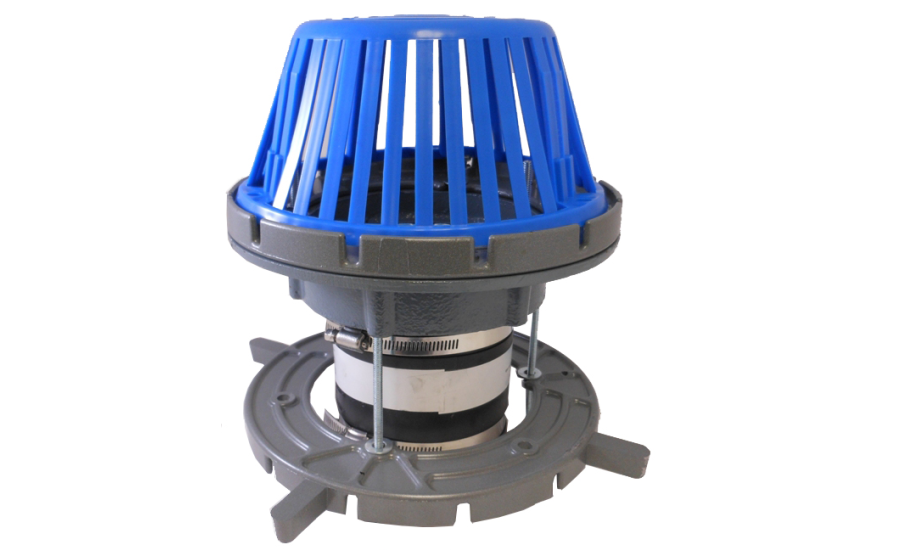

BELOIT, Wis. – Mule-Hide Products Co. has expanded its offering of multi-system accessories with a selection of roof drains for new construction and retrofit applications.

For new construction projects, contractors can choose from kits featuring drains with heavy-duty bodies made of injection-molded PVC or epoxy-coated cast iron.

For retrofit applications, options are available to suit the requirements of any project, and all are designed for quick, easy installation. Aluminum and copper outlets are offered. Flange material choices include aluminum, copper, asphalt and, for contractors who prefer to heat-weld the flange to the outlet, TPO and PVC.

All of the new construction and retrofit drains offer the following features:

• Availability in multiple sizes to suit any project.

• Elevated strainer ring risers to increase water flow through the drain.

• Clamping rings with undersides that are ribbed and embossed to help ensure that the drain ring is tightly secured to the roofing membrane.

Drains for new construction applications also have the following features:

• They meet and exceed ANSI, ASEE, PDI and IAPMO plumbing standards.

• A heavy-duty epoxy-coated aluminum clamping ring – 1¼ inches high with 12 scallops and seep holes on the bottom – to maximize drainage.

• A flexible rubber coupling to connect the drain to a PVC or cast iron pipe.

• An aluminum underdeck clamp to fasten the drain securely to the roof deck.

Drains for retrofit applications also offer the following features:

• They meet and exceed ANSI/SPRI RD1 standards for water flow.

• A large stud diameter that increases hardware strength.

For more information, visit mulehide.com or call 800-786-1492.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!