X-MAT Advances Developments in Creating Roofs, Homes Out of Coal

A conceptual drawing of X-MAT's home built from coal-derived materials. Images courtesy of X-MAT.

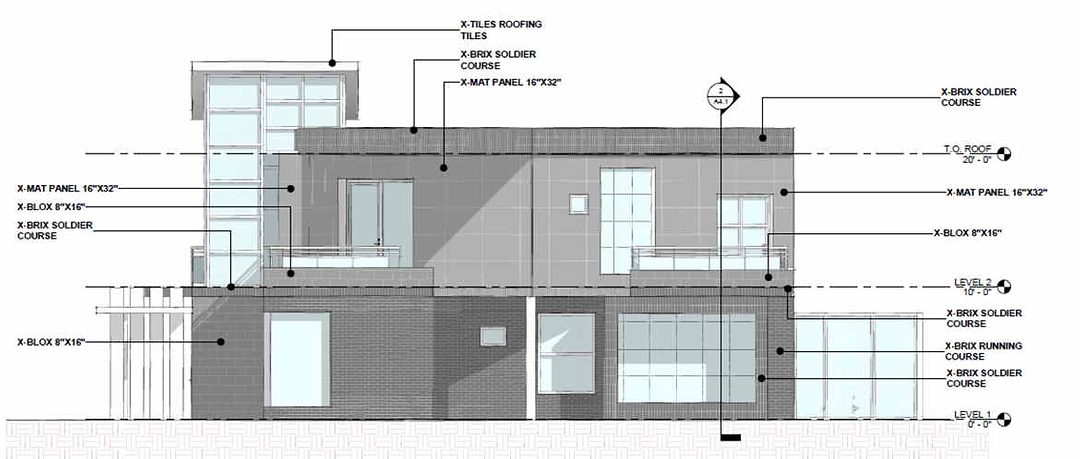

A conceptual drawing listing various X-MAT materials used in the construction of a home.

X-MAT's X-TILES.

ORLANDO, Fla. — In today's world, coal is often seen as an antiquated source of fuel that harms the environment, but Florida-based Semplastics believes the substance can have a second life as a material for constructing not just roofs, but entire houses.

Based on the company's latest developments, creating homes made of coal-derived materials might be a reality sooner than later. X-MAT, the Advanced Materials Division of Semplastics, revealed it's taken massive strides in the creation of its revolutionary coal house, including the ability to produce 100 square feet of its coal-based roof tiles.

Initially, X-MAT developed a polymer-derived ceramic mixed with coal to create its X-TILE, an eco-friendly roofing tile that is fireproof and can withstand extreme temperatures between -238 degrees to 2,012 degrees Fahrenheit. The tiles are also said to be two to four times stronger and weigh 30% less than ceramic roof tiles.

“We’re making great progress in the development of the X-TILE,” said Bill Easter, founder of Semplastics and X-MAT. “We’re reimagining coal in a way that’s never been done before — the innovation and technology we’ve created is completely unprecedented.”

In December 2020, the company revealed it received a $625,000 contract from the Department of Energy’s National Energy Technology Laboratory (NETL) to create coal-derived building materials needed to construct an entire house. If there's a company that can pull it off, it's X-MAT — launched in 2013, the company's projects include recycled lithium ion batteries, X-TILE and high-temp plastics, and has worked with NASA and Space Florida.

The company has made great progress in the past six months, meeting numerous milestones to begin production on structural columns, walls, bricks, roof tiles and other crucial elements of construction made primarily from coal. The building materials will resemble the X-TILE product in being extremely strong, non-toxic, fire resistant and light weight. A conceptual drawing of the coal home lists X-TILES for the roof alongside building materials with names like X-BRIX, X-BLOX and X-MAT panels.

X-MAT's progress includes the establishment of a new pilot line in Oviedo, Fla., the creation of numerous Villa-Tile prototypes and the commission of a first-of-its-kind firing kiln. With this kiln, X-MAT will be able to produce 100 square feet of X-TILE in June 2021. The company has also established an advisory board and completed preliminary renderings of a coal building.

“We’re giving coal a second chance,” said Easter. “With X-MAT’s technology, coal can be the future of sustainable living.”

In addition to these advancements, X-MAT has also seen growth in the amount of space it has to create these products. With the expansion of X-MAT’s facilities in Oviedo and in Bluefield, W.V., the company increased its prototype production capabilities for building materials.

Semplastics says the progress in the creation of the coal house and related materials were made possible with government funding, with $6 million raised in contracts and grants from the Department of Energy.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!