Event News

Owens Corning Showcases Composites at CAMX 2024

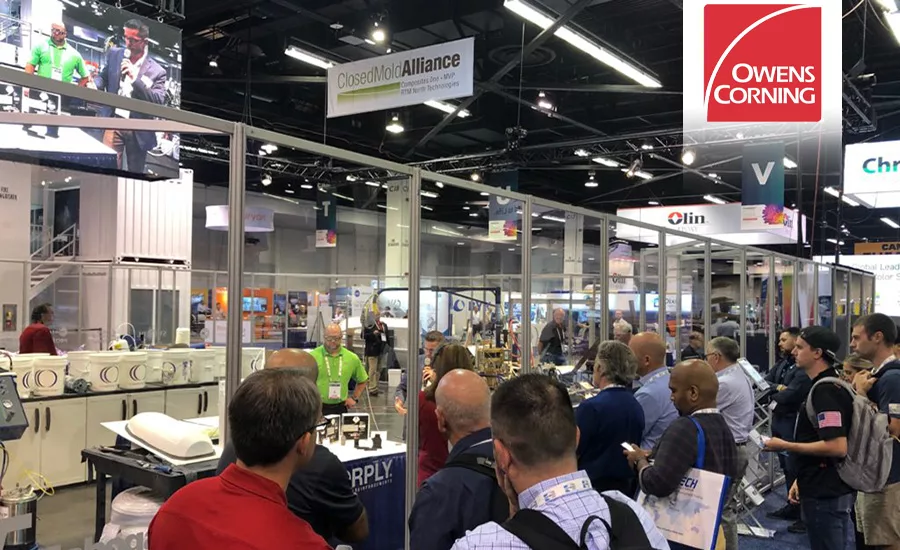

Composites experts from Owens Corning are on hand showcasing composites at CAMX 2024 in San Diego, Calif., now through September 12. OC says its participation supports efforts to grow material replacement and partner with customers for innovation and sustainability.

— Image courtesy of CAMX

2.5 MIN READ

Owens Corning's composites experts are showcasing composites to “Make More Possible” at CAMX 2024, which is taking place in San Diego, California, from now through September 12.

OC said its participation in CAMX 2024 supports efforts to grow material replacement and further its strategy of partnering with customers to boost product innovation, productivity, and sustainability to “Make More Possible.”

Representatives from OC’s global team of composites experts and business leaders are on hand throughout the event to discuss the company’s array of industry-leading solutions, including:

-

SUSTAINA Glass: Innovation Beyond Performance. Manufactured from a combination of post-industrial circular content and traditional glass input materials, SUSTAINA is Owens Corning’s latest glass innovation, supporting its commitment to help protect the planet without compromising product performance.

SUSTAINA is UL-certified with 35%, 50%, and 100% circular content.1 Owens Corning Composites created this advanced glass technology as an input material for a range of products, including its multi-end roving line designed for sheet molding compound applications and Type 30 single-end rovings designed for pultrusion and long-fiber thermoplastic processes.

-

HP2 Glass: High-Performance Composites. The second generation of Owens Corning’s high-performance glass boosts mechanical properties, enhancing part performance and enabling cost optimization through redesign. HP2 glass reduces weight profiles — by more than 9.5% for pultrusion2 and more than 11% in filament winding for poles2 — saving material cost. HP2 also enhances the performance of composite structural elements.

With processes including pultrusion, filament winding, and long-fiber thermoplastics, HP2 is sized to seamlessly integrate with processing characteristics of most Owens Corning Type 30 single-end roving products.

-

Smart Packaging Solutions. The new OPTISPRAY 4-high pallet-line enables one-third more product per pallet, saving warehouse space, reducing waste, and avoiding unnecessary material handling. Owens Corning Composites is also refurbishing and reutilizing pallets shipped from one of its North American manufacturing locations in partnership with customers and suppliers.

This process has reduced the number of new pallets needed for OC’s operations and eliminated the need for one of its customers to manage pallets in their operation. Together, these actions have helped preserve the equivalent of more than 800 trees.3

-

Local Supply Benefits Productivity. Owens Corning Composites experts will share details from a case study demonstrating how local supply can boost productivity. Among the benefits of local supply are reduced delivery lead times, fast service, agile response, and inventory optimization.

Local supply also contributes to reduced carbon emissions generated by U.S. customer locations sourcing within the region versus products sourced from Asian locations.

For example, a product delivered to Dallas, Texas, from an OC location in the U.S. can result in more than three times lower CO2 emissions than a product sourced from an Asian supplier location.

Billed as North America's largest composites and advanced materials event, CAMX 2024 is taking place at the San Diego Convention Center through September 12.

Owens Corning is exhibiting in Hall C, Booth X21.

For more information, visit owenscorning.com.

- 1 – UL-Certified through mass balance. Document # 230350-4210, 230351-4210, 230352-4210 found through https://spot.ul.com/.

- 2 – Data and results are based on modeling analysis where standard Advantex Glass was replaced with HP2.

- 3 – Owens Corning Composites Pallet Take Back and 4-High Pallet programs, 2019-2024.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!