Project Profile: Historic Philadelphia Girls' Rowing Club Gets New Vibrant Red Roof

The high-performance coating used on the historic boathouse will keep the roof’s aesthetic appearance looking bright barn red for many years ahead.

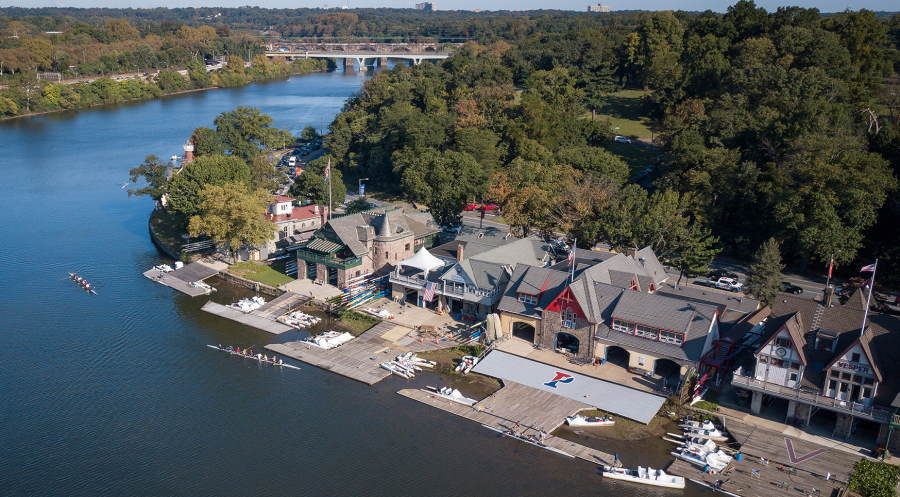

As the earliest of the surviving Boathouse Row structures, the home of the Philadelphia Girls' Rowing Club (far left) serves to anchor the other elegant boathouses along the banks of the Schuylkill River.

Showing signs of significant weathering, degradation, and color fade, the roof was in dire need of a recoating.

An aerial photo showing the project after its completion.

The Philadelphia Girls' Rowing Club is an amateur all-female rowing club located on Philadelphia’s picturesque Boathouse Row—a national historic landmark and birthplace of American rowing. With a signature “barn-red” roof and prominent location, its home serves to anchor the other elegant boathouses along the banks of the Schuylkill River.

Listed in the Philadelphia Register of Historic Sites, the two-and a-half-story Italianate style clubhouse — the earliest surviving structure on Boathouse Row — stands largely unchanged from the days in which it was built in 1861. A hipped roof — double-pitched in the front — and topped by a distinctive square cupola imparts much of the building’s architectural character and aesthetics.

Challenging Environment

Situated low along the riverbank, the historic boathouse is subjected to wind-driven heavy rains and water from falls downstream. Extreme seasonal temperature fluctuations of the Mid-Atlantic region, the urban environment’s acid rain, and fine soot in the air are additional challenging weathering conditions.

Upon inspection of the roof by professionals at Cooper Roofing Corp., it was determined that the roof coating applied seven years earlier reached the end of its useful service life.

“There was noticeable chalking, blistering, alligator cracking, and dulling of the surface as a result of dirt, mildew, and other airborne pollutants,” said Terry Cooper, owner of Cooper Roofing. “The roof clearly needed to be recoated to ensure protection of the building envelope, as well as to revitalize its iconic barn-red aesthetic appearance.”

Desired Longer Service Life

For the roof restoration, club members wanted a durable solution that would stand up to the challenging weathering conditions much longer than the typical seven-year life cycle of an elastomeric coating. Long-lasting color retention of the iconic red roof was also of vital importance.

In search of a high-performance coating to provide the demanding durability and aesthetic performance requirements, Cooper Roofing reached out to the experts at Acrymax Technologies. For nearly seven decades, the company’s engineered coating systems have been used to overcome very challenging problems at countless historic roof restoration projects.

“We are deeply committed to the preservation of historic roofing systems and each product we recommend is carefully chosen to achieve a specific objective,” said Eric Bennung, product development engineer at Acrymax. “For the roof topcoat, we selected our AF-4400 coating, which combines the flexibility of an elastomeric acrylic with the superior durability properties of Kynar Aquatec® technology.”

Coatings formulated with water-based Kynar Aquatec PVDF emulsions provide the same long-lasting durability, extreme weatherability, and color-retention properties as Kynar 500® PVDF resin-based coatings, which can withstand extended exposure to temperature extremes, ultraviolet rays, and other harsh climate conditions. However, unlike factory-applied Kynar 500® resin-based coatings, coatings based on Kynar Aquatec® PVDF emulsions can be field applied to a variety of substrates and as a finish coat over acrylic basecoats. They also offer outstanding resistance to dirt, staining, algae, mold, and corrosion, and they are excellent at preventing water from penetrating the surface.

Restoration Gets Underway

Cooper Roofing started the job by power washing the entire 3,150-square-foot roof to clean off any debris, dirt, chipping paint, and other contaminants that can interfere with adhesion. Workers next repaired low areas, ponds, blisters, and cracking where water might pool up and cause leaking issues.

Once the surface was properly prepared, Cooper Roofing roller applied an acrylic elastomeric basecoat (Acrymax AF130XT) at an application rate of 1 gallon per 100 square feet (16 wet mils). This ensured a minimum dry-film thickness of 8.5 mils. The crew then roller applied the barn-red AF-4400 high-performance topcoat to achieve specified dry film requirements and to provide a uniform, pinhole free, and continuous coating film.

According to Chase Cooper, project manager for the roofing work, the high-performance topcoat was very user-friendly and easy to work with. “From an applicator’s point of view, I was very pleased with the end result and would definitely recommend it to customers who are looking for a high-quality roof coating that will last for 15 to 20 years or more,” he said.

Long-Lasting Protection and Beauty Restored

The restoration was completed over a two-day period when the weather was mild and dry. “By applying Acymax’s durable AF-4400 topcoat formulated with Kynar Aquatec® PVDF resins, we can expect the new roof to stand up to the area’s challenging weathering conditions for a very long time, ” said Bennung.

“The new roof on our 150-year-old clubhouse looks great and we are very happy with how these three companies took charge of the entire process in providing us with a superior, cost-effective restoration solution,” said Sophia Socha, president of the Philadelphia Girls' Rowing Club. “They went through great lengths in matching the historic color needed and applying a premium coating product to keep its aesthetic appearance looking bright barn red for many years ahead.”

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!